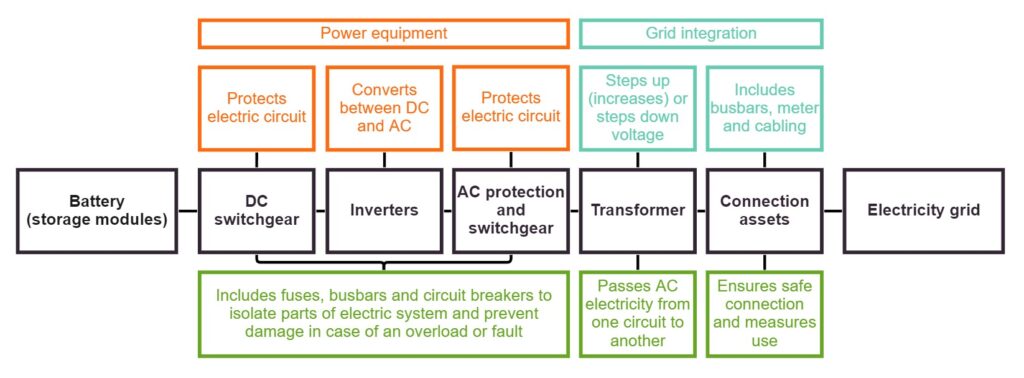

The figure below outlines the hardware associated with a neighbourhood battery, including its connection to the grid and its digital management. Projects will need to determine the technical requirements for each of these components prior to going out to market and in practice, the relative importance of each technical requirement will be different for each battery and each setting e.g. urban versus regional. The experiences of YEF and their battery selection process can be read about in an interview with YEF’s Community Battery Project Manager, Chris Wallin.

The battery

The main chemical battery type currently using in residential and neighbourhood-scale storage in Australia and globally is lithium-ion. This is because of its highly competitive energy density, rechargeability, efficiency, manufacturing costs, and scalability.

There are however also other chemical battery types on the scene that are increasingly competing with lithium-ion, especially with rising concerns over the availability of raw materials like lithium.

| Battery type | Comparison to lithium-ion | Examples |

|---|---|---|

| Dual carbon | Can charge 20 times faster Has comparable energy density Improved safety Uses cheaper raw materials | There are currently no examples of dual carbon batteries in use in Australia but there are in Japan |

| Sodium-ion | Uses abundant and inexpensive materials Could achieve a higher energy density | There are currently no examples of dual carbon batteries in use in Australia but there are in Japan |

| Zinc-ion | Considerable improvements to safety Uses cheaper materials Has a longer lifespan Heavier | No but has seen recent development in R&D |

| Vanadium redox flow | Lower energy density so larger spatial footprint Can achieve 20 year lifespan Experience no degradation over their lifetime Have no limit on energy capacity per unit Can have very low production costs | South Australia from the end of 2020 trialled a utility-scale vanadium flow battery |

As part of procuring your battery, you need to connect the procurement process and the battery specifications with your purpose, objectives and the services you intend to deliver. If you have a commitment to social development, you may seek to support a local manufacturer (if you can find one that meets your needs) or an international manufacturer that has a good social record. If your main commitment is environmental, you will want to consider the embedded emissions and environmental costs of manufacture (including options for recycling) and make decisions on that basis. Obviously, the size of the battery and metering requirements (see below) will need to support the services you intend to provide. The size and look of the battery also influence its amenity, depending on the site.

The technical requirements can be obtained through consultation with your energy expert (overview of power equipment and grid connection quote provided by DNSP), specifications of your selected battery (switchgear and inverter ratings), and arrangements made with your DNSP (grid connection assets). During the feasibility stage, you should request a quote for network connection cost and requirements from your DNSP. This should be revised once you select your battery technology and confirm its capacity. A key hardware component of your battery’s grid connection is the meter, which will allow telemetric measurements of the battery. For example, to enter the FCAS market, you will require accurate interval measurements for your battery (i.e. a type 4 smart meter).

In some cases, a battery will also require its own point of supply (limit one per lot), which is the point where the aerial service cable is connected to the private pole. This may require a property sub-division or exemption for an additional point to be installed.

To unlock the greatest possible benefits of your metering infrastructure, it would be advantageous for the metering to allow all stakeholders (the public and DNSPs) to view this data in near real-time. This can be done through software e.g. an app or website that has a dashboard of the battery’s current behaviour and state of operation. For example, the YEF Solar Sponge battery has a live online dashboard that shows the battery’s state of charge and its last 24 hours of charging and discharging operation. Only with this sort of monitoring would householders be able to adjust their behaviour to take advantage of locally available power generation. An online dashboard will also help provide transparency around the battery’s operation, as per its selected optimisation and control system.

You also need to factor battery maintenance into your model and budget (see battery maintenance section). The battery will need regularmaintenance by an accredited technician, as well as more frequent visual checks. You should also have contingency plans for if the battery malfunctions or is damaged, or if it is exposed to temperature extremes.

The battery capacity will be determined through the feasibility study and will be dependent on many factors including available capital, space, connection limits, local solar generation and peak demand. The higher the capacity, the more revenue and the bigger impact on local solar soaking and peak demand management. However, higher capacity is more expensive (costs are on a kWh basis), takes up more room, makes more noise and will be potentially of more concern for the DNSP who will need to ensure the operation of the battery doesn’t overload the network.

Optimisation and control system

The optimisation and control system refers to the software and APIs required to digitally manage the operation of your battery and respond to real-time data on spot price, load, and PV generation. Depending on your chosen system, this will include digital communication and coordination between a number of different proponents.

For example, the control system may involve coordination between several project partners including:

- The battery itself

- A software, that translates an optimisation code and interfaces with the battery,

- Optimisation code that provides scheduled and optimised code for the battery’s operation and for its interface with the battery’s software, and

- A retailer/aggregator.

The choice of optimisation and control system will need to be made based on the ownership and stakeholder participation model that has been chosen for the project. The relevant tariffs and services that the neighbourhood battery is offering will then determine the particular objective(s) that are being optimised and controlled for.

Optimisation software for operating a neighbourhood-scale battery is still in development. Prices can vary significantly, and purchasers should use caution to ensure the promised capability can be provided in practice.

The Australian National University c3x software used by the YEF battery is open source. When selecting software, you should also consider potential security and privacy issues that could arise. For example, one project encountered numerous issues using an overseas software provider because customer data was unable to be sent offshore, meaning the company had to guarantee only Australian based staff would work on the project.

To schedule and optimise the battery’s operation, forecasted data, including that for solar generation, load, and price, will likely be required. As forecasts will always include a level of inaccuracy, flexibility and measures to account for this inaccuracy will need to be included in the design of your optimisation and control system. For example, the YEF battery has introduced risk measures to mitigate the possibility of the battery incorrectly charging off high-cost electricity to try and make profit off even higher forecasted spot prices (that if don’t occur leave the battery owner at risk of absolving that cost).

System and market integration

To enable participation in AEMO-run markets for energy and ancillary services, the software for the battery will require integration an electricity retailer’s internal systems. Note it is possible for neighbourhood battery operators to integrate directly with AEMO via Marketnet, however this is costly to setup and maintain, and generally is only used by market participants i.e. retailers. Retailer partners generally have API interfaces that can be integrated with battery control system. Additional integration can be required with the local FCAS hardware.

Integration with internal DNSP systems may be also required. DNSPs are expected to offer Dynamic Operating Envelopes as part of neighbourhood battery connection agreements. This would occur using the IEEE 2030.5 Common Smart Inverter Profile (CSIP-Aus) interface. Additionally, the neighbourhood battery may chose to offer Network Support Services to the DNSP. These services require further integration with DNSP systems.

Some DNSPs are exploring dynamic tariffs, where the tariff rates vary based on forecast network conditions. Participating in these solutions also require integration with DNSP systems.