By Dr Idris F Sulaiman, independent energy and ICT consultant

10 February 2023

At the last G20 Summit and UN-CoP27 conference last year, governments around the world made a commitment to decarbonisation targets by the middle of the century. This necessitates an acceleration towards a world powered by various renewable energy sources, some of which are intermittent in nature and need to be supported through the addition of battery storage. While lithium-ion technology is not new and has been in commercial use for battery storage for almost 30 years, it is difficult to verify claims made by manufacturers about performance, integration, and installation of battery packs. This is true for Australia, Indonesia or anywhere in the world. In late December 2022, under their own initiative, a team of Indonesian engineers from the Centre of Excellence for Electrical Energy Storage Technology from the Universitas Sebelas Maret Negeri Surakarta (UNS) – the only state university in Indonesia with its own battery laboratory – made a historic visit to two Australian battery laboratories as part of its exploratory mission. These missions paved the way towards greater collaboration between the two countries.

In Australia, most lithium-ion solar battery types should be able to last up to 10 years under normal usage if not subjected to extreme temperatures (the definition of which may vary in different countries). Nominally, batteries should be able to last as long as their warranty period – which for most models is 10 years. In reality there isn’t enough market data to show whether modern solar batteries typically last that long in real-world home installations. Newer generations of batteries that have only been on the market for a few years have yet to have their longevity and performance tested.

Here is where laboratory testing of battery durability and lifespan matters. The recent solar battery trial in Australia by ITP Renewables, based at the Canberra Institute of Technology (CIT) has indicated a high rate of failure, with few of the batteries in that trial operating without major problems. According to the laboratory lead Mr. Philippe McCracken: “Most of the products tested either had operational problems the manufacturer had to step in to resolve, or failed and needed to be replaced, or failed and couldn’t be replaced, for example because the manufacturer was out of business or would no longer support that product”. He further added that: “the most expensive models may not necessarily have the best performance, and in fact, one of the lowest priced ones had demonstrated a superior performance in its capacity retention”.

Professor Wahyudi Sutopo, the leader of the UNS Team said: “These results and our visit to the laboratory have indeed been an eye-opener. The fact that price doesn’t guarantee necessarily a better performance is very interesting indeed”. He further added that “visiting the battery laboratory trial has encouraged the team that it would be important to establish a similar facility in Indonesia. Both commercial businesses and individual consumers need awareness raising on the performance of residential and commercial storage batteries as well as the batteries for electric vehicles that are available in the Indonesian market. By providing them with critical data, this will greatly assist in increasing accountability and enhancing consumer support from battery manufacturers”.

To conduct the above lithium-ion battery trial, ITP Renewables was supported by $1,290,000 of grant funding from the Australian Renewable Agency (ARENA). This project analysed the performance of 26 leading batteries, comparing major lithium-ion battery brands to existing and advanced lead-acid battery technologies, a zinc-bromide flow battery, an aqueous hybrid ion battery, and a sodium nickel chloride battery. The trial ran from March 2016 until December 2022 producing a dozen technical reports published on the ARENA website. In disseminating the information to the public, ITP Renewables was also supported by the Australian Consumers Association’s CHOICE magazine who publicised the comparative test of storage batteries under an accelerated program to raise consumer awareness on the general details of what to consider to buy and whether a battery is likely to be cost-effective if purchased in the Australian market. For a relatively new and large market such as Indonesia, there is a critical need to independently test the performance of each of the major brands of batteries within a laboratory setting that simulates the conditions that the batteries would be expected to face in Indonesian conditions. Consumers would then be able to make better informed choices between the different available brands and understand whether a battery is likely to be cost-effective within the Indonesian market.

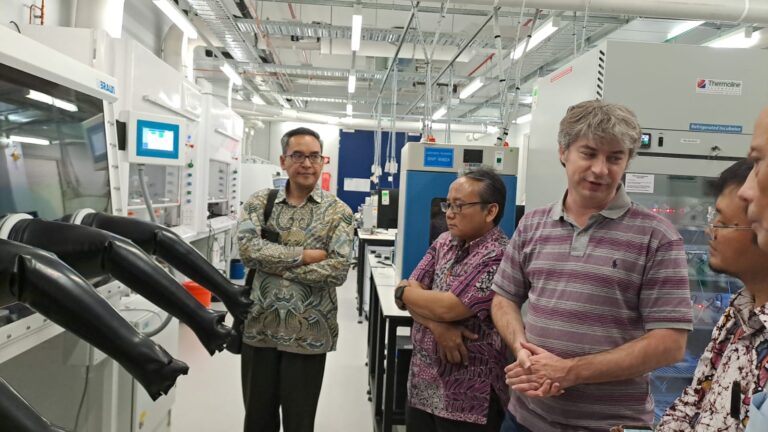

Visit to ANU battery laboratory for testing advanced lithium and next-generation batteries

Given the central role that batteries will play in our energy infrastructure and decarbonised future, many laboratories are researching technologies and manufacturing techniques to increase batteries’ energy and power density. Since 2012, the Centre of Excellence at the PUI-UNS – part of the Research Group of Industrial Engineering and Techno-Economy at UNS in the city of Surakarta (Solo), Central Java – has achieved several research milestones, spun-off a number of technology start-ups, and plans to become the leading energy storage development centre in Indonesia. The Centre has been conducting research on cell development and fabrication, testing of battery performance, and developing active battery materials.

With these plans in mind during their visit to Canberra, the UNS Team also were able to visit the Battery Materials and Energy Storage Laboratory, one of the two facilities managed by the Battery Storage and Grid Integration Program at the Australian National University. This Laboratory opened in February 2021 and is tasked with conducting research on development and fabrication of lithium-ion batteries, optimising their electrode materials, and testing and assessing recycling and reuse options.

The ANU facility is of interest to the UNS team as its focus is the investigation of next-generation storage technologies, engaging in collaboration with industry in testing and benchmarking lithium-ion battery electrode materials. The fabrication of battery materials and cells is not possible without appropriate characterisation to confirm their quality and structural characteristics. In this regard, the advanced application of spectroscopy to battery materials sensitive to the atmosphere is a particular specialisation of the Laboratory.

According to Associate Professor Alexey Glushenkov, Research Lead of the program at the ANU Research School of Chemistry, with increasing use of lithium-ion batteries in multiple new applications (most notably in the electrification of transport), the need for the recycling and reuse of batteries is becoming more apparent. The ANU Laboratory has been working with industry partners, particularly where materials from batteries can be directly recycled into new lithium-ion or alternative battery technologies.

As lithium-ion batteries are used in increasing numbers for residential, commercial, and utility-scale battery storage, electric vehicles, and consumer products, supply chain constraints will become a challenge. Therefore, the ANU Lab is researching non-lithium battery technologies, including sodium-ion, potassium-ion and dual-ion battery chemistries. They also research hybrid capacitors made with materials such as lithium-ion to address the challenges of traditional batteries with respect to recharge time and delivery of very large power pulses.

Another laboratory enabling cutting-edge research to optimise power systems is the ANU Distributed Energy Resources Laboratory (DERlab) which is a state-of-the-art testing facility which mirrors the energy grid. It opened in July 2021 with ITP Renewables being lead partner in the project.

Upon the conclusion of the visit, Professor Sutopo stated that the ANU Battery Lab is working in very important basic research areas particularly providing insightful utilisation of battery materials and cells as well as alternative battery storage solutions that utilise more sustainable materials and chemical elements. “Such frontier areas of collaboration are ripe for Australia and Indonesia to become partners in creating new added value”.

At the recent Business 20 (B20) Summit under the G20 Framework last November 2022 in Bali, President Joko “Jokowi” Widodo invited Australian Prime Minister Anthony Albanese to work together in renewable energy and specifically called on Australia to collaborate producing batteries for electric vehicles. His reasoning was that as Indonesia had large reserves of nickel, while Australia had significant lithium deposits, putting the two countries in a strong position for EV cooperation. “It’s clear that there are ample opportunities for the two countries to collaborate in cutting-edge research on battery materials as well as in improving battery performance – these are bound to benefit both nations (as well as third countries in the Indo-Pacific region)” said Dr Mukhamad Najib, the Education Attaché at the Indonesian Embassy Canberra who accompanied the UNS team throughout both laboratory visits. He added, “the UNS visit was very timely and is exemplary for other Indonesia universities to follow in this important field of electric battery development and to take the initiative to explore and meet with new counterparts in Australia”.

There is no doubt that such visits could pave the way for further exchanges and eventually transfer of technologies that would bring new scientific capabilities. This would further open up new markets in both countries in support of greater uptake of renewable energy and energy storage – contributing towards achieving each country’s respective commitments to decarbonisation targets.