There has been a considerable increase in the integration of renewable resources into electricity generation and the adoption of electric vehicles around the world. The total electricity generated from renewable resources in Australia accounted for 24 per cent in 2019. The cumulative sale of electric vehicles (EVs) around the world reached as much as 2.1 million by the same year. According to Australian National Greenhouse Accounts, the electrification of transport is highly important for the minimisation of climate change, and the automotive sector contributes approximately 20 per cent of total greenhouse gas emissions in Australia. Lithium-ion batteries, introduced in 1991 by the Sony Corporation, are the key technology for storing energy generated from renewable resources and for enabling EVs. According to Roskill, a leading research and consultancy firm specialising in metals, minerals and chemical industries, the demand for lithium-ion battery production is predicted to increase by tenfold to 1800 GWh globally, by 2029 from the manufacturing levels in 2019.

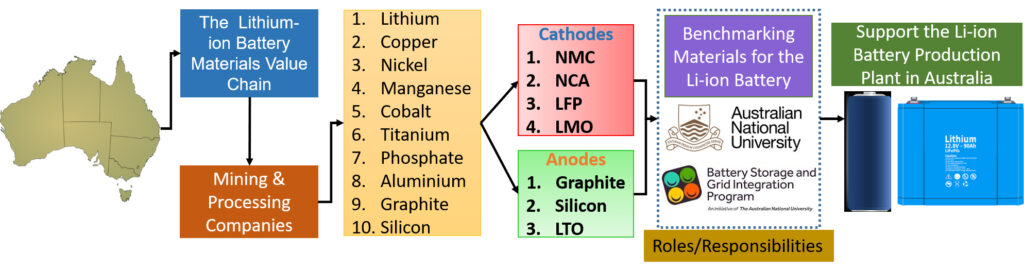

Lithium-ion battery production involves three major streams; preparation of materials; cell manufacturing and; assembly of battery packs. A range of positive electrode (cathode) materials such as LiNixMnyCozO2, LiNixCoyAlzO2, LiFePO4, LiCoO2 and LiMn2O4 are well-established and used for fabricating lithium-ion batteries in industry. Graphite and lithium titanate are used as negative electrode (anode) materials, depending on the application. Recently, silicon has also emerged as a new high-capacity negative electrode candidate with commercialisation prospects. Australia has the third largest reservoir of lithium resources in the world and substantial quantities of many other minerals necessary for the fabrication of lithium-ion batteries. Multiple companies are active in the minerals space, aiming to produce graphite, silicon-based negative electrode materials and a range of positive electrode materials, including LiFePO4 and LiNixMnyCozO2. There is also a growing interest in developing the whole battery supply chain locally in Australia, stretching from mining and synthesis of materials to fabricating Australian-made batteries.

“Australia is in the midst of a global energy revolution associated with the use of batteries for grid storage and transport,” said Dr Alexey Glushenkov, Research Leader for the Battery Storage and Grid Integration Program at ANU. “We offer services to mining companies and industry enabling the assessment of battery materials, their quality and performance versus comparable materials in the market.”

The ANU battery team has vast experience in the synthesis and testing of various materials for lithium-ion batteries. The team can provide benchmarking of battery materials versus established industry standards and perform characterisation of materials using a range of chemical and physical techniques.

Steps involved in studying the feasibility of a material in the battery storage application:

1. Physical/chemical characterisation:

The structure and morphological characterisation studies of the material are performed using various techniques such as X-ray diffraction, scanning and transmission electron microscopy, spectroscopic techniques and low-temperature N2 adsorption.

2. Electrochemical characterisation:

Electrochemical properties of a material are analysed using electroanalytical techniques (galvanostatic charge-discharge, cyclic voltammetry and electrochemical impedance spectroscopy). The properties of the material are studied initially in a half-cell, i.e. against a lithium reference metal, followed by their evaluation in a full cell (against a practical opposite electrode).

3. In-operando studies:

The phase and morphological transformations of a material during its electrochemical activity may be studied using in-operando X-ray diffraction, transmission electron microscopy or micro-CT analysis.

4. Failure analysis:

The electrode failure analysis is conducted using a broad range of analytical techniques and instrumentation available in ANU laboratories.

Our research activities can assist in the development of the battery materials industry in Australia. These activities are a part of a broad research program enabled by the newly established ANU Battery Lab.

Contact: Dr Alexey Glushenkov, Research Leader, Battery Storage and Grid Integration Program, ANU. Email: alexey.glushenkov@anu.edu.au